Is this a Dream or is that really my LS7? Page 9 of 10

Is this a Dream or is that really my LS7?

CAC Does the Corvette Engine Building Experience - Page 9 of 10

by Hib Halverson

© September 2012

No use without permission, All Rights Reserved

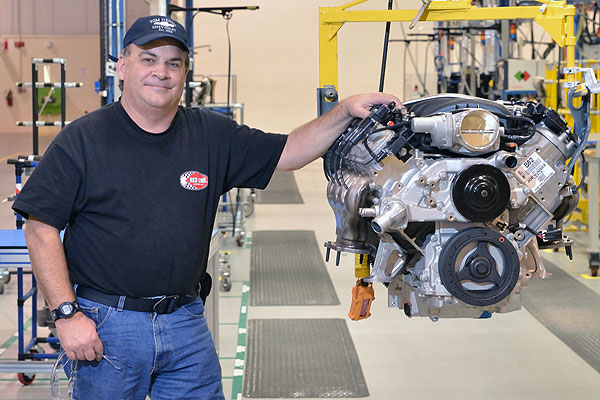

Mike and I rolled the engine stand to the next station. This was where my LS7 started to look like a real engine. I installed the rocker covers, the coils, spark plugs, the intake manifold-actually, it's an entire sub-assembly of the manifold, injectors, fuel rails and throttle body, put together by a supplier-and the plug wires. This station was also where I got to apply the special "Engine Build Experience" ID plate with my name on it to the passenger side fuel rail and the stickers with the job number, bar code and my name to the ends of the left head. That was pretty damn cool.

The final three major operations were: 1) tighten the harmonic damper bolt, done with another one of those big, overhead-mounted, handle-bar operated, torque-angle-sensing power tools, 2) put the exhaust manifolds in place, 3) install the flywheel and the clutch and 4) weigh the engine. Ladieeees and gentlemen, in this corner, weighing in at 454.2-lbs., we have the highest specific output V8 in the country-THE L-S-sevennnnn.

All done and ready for "cold test" and "hot balance".

Image: Mark Kelly/GM Powertrain