Ruthless Pursuit of Power: Our In-Depth Look at the 2008 Corvette LS3 Engine - Page 6 of 6

Ruthless Pursuit of Power: 2008 Edition - Page 6 of 6

Our In-Depth Look at the New 2008 Corvette LS3 Engine

|

|

© 2007 by Hib Halverson

No use without permission, All Rights Reserved

Cam and Valvetrain

The Gen 3/4 valvetrain continues to evolve with previous Z06 features appearing in base engines. The LS3 camshaft is based on the one used in the C5Z's groundbreaking, LS6. Its intake lobe comes from the '02-'04, 405-horse cam. The exhaust profile is from the 385-horse LS6 of 2001 and the LS2 of '05-'07. For LS3, in order to reduce overlap, lobe separation was increased a degree over the LS2 cam. The net sum of all this was more intake airflow and a smoother idle.

Camshaft Profile, Intake Comparison

(All lift figures are valve lift)

| year RPO

|

int. lift |

int. dur. at .004 |

int. dur. at .050 |

int. open at .004 |

in. close at .004 |

in. open at .050 |

in. close at .050 |

int. CL |

int. area |

int. area increase |

|---|---|---|---|---|---|---|---|---|---|---|

MY01 LS6

|

13.34 mm .525 in |

270° |

204° |

9° BTDC |

81° ABDC |

18 ATDC |

42 ABDC |

118° ATDC |

1862.9 mm/deg. |

n/a |

MY02 LS6

|

14.01 mm .551 in |

267° |

204° |

7° BTDC |

80° ABDC |

19° ATDC |

43 ABDC |

120° ATDC |

1936.9 mm/deg. |

4% |

MY05 LS2

|

13.34 mm .525 in |

270° |

204° |

9° BTDC |

81° ABDC |

18° ATDC |

42 ABDC |

118° ATDC |

1862.9 mm/deg. |

0 |

MY06 LS7 |

15.06 mm .593 in |

276° |

210° |

8° BTDC |

88° ABDC |

18° ATDC |

48° ABDC |

122° ATDC |

2166.4 mm/deg. |

16% |

MY08 LS3

|

14.01 mm .551 in |

267° |

204° |

7° BTDC |

80° ABDC |

19° ATDC |

43 ABDC |

120° ATDC |

1936.9 mm/deg. |

4% |

Camshaft Profile, Exhaust Comparison

(All lift figures are valve lift)

| year RPO |

exh. lift |

exh. dur. at. .004 |

exh. dur. .050 |

ex. open .004 |

ex. close .004 |

ex. open .050 |

ex. close .050 |

exh. CL |

exh. area |

ex. area change |

|---|---|---|---|---|---|---|---|---|---|---|

MY01 LS6

|

13.33 mm .525 in |

275° |

211° |

65° BBDC |

30° ATDC |

37 BBDC |

6 BTDC |

114° BTDC |

1914.6 mm/deg. |

n/a |

MY02 LS6

|

13.91 mm .547 in |

282° |

218° |

69° BBDC |

33° ATDC |

42 BBDC |

4 BTDC |

115° BTDC |

2046.6 mm/deg. |

8% |

MY05 LS2

|

13.33 mm .525 in |

275° |

211° |

65° BBDC |

30° ATDC |

37 BBDC |

6 BTDC |

114° BTDC |

1914.6 mm/deg. |

0 |

MY06 LS7 |

14.95 mm .589 in |

296° |

230° |

81° BBDC |

35° ATDC |

53 BBDC |

3 BTDC |

119° BTDC |

2359.4 mm/deg. |

23% |

MY08 LS3

|

13.33 mm .525 in |

275° |

211° |

66° BBDC |

29° ATDC |

38 BBDC |

7 BTDC |

115° BTDC |

1914.6 mm/deg. |

0 |

The mix of lobe profiles, also, means there are two different base circles, 19-mm for the intake and 19.3-mm for the exhaust. Because of the different base circles, to keep valve train geometry optimized, two different valve lengths are used in the LS3 with intakes 0.6-mm. longer than exhausts.

We interviewed valvetrain Design Release Engineer, Jim Hicks several times in recent years for stories on LS1, 2 and 6 and he told us, "All our cams (prior to LS6) had the same base circle radius. We had a problem, if we wanted higher lifts: the nose of the cam would approach the same diameter as the cam bearing journals or even exceed them.

"Obviously, that means you can't install the cam in the engine-little bit of a problem. Your only alternatives are to increase rocker arm ratio, which we weren't going to do (for this engine), or reduce the base circle radius."

The first base circle reduction, for the '01 LS6, did not require a change in any other valvetrain part, however, the 405-horse cam for '02 was a different story as was the LS3's intake lobe, which uses the same profile.

"I wasn't comfortable reducing base circle that much," Hicks told us, "without compensating for it somehow, because the position of the plunger within the hydraulic lifter is not optimal any more-you're too high in the lifter.

"There are different ways to correct the geometry. The one we selected to minimize the impact on our manufacturing operations was to increase the length of the valve. The valves in the 02 LS6 and intake in the LS3 are 0.6-mm. longer than the valves in other engines."

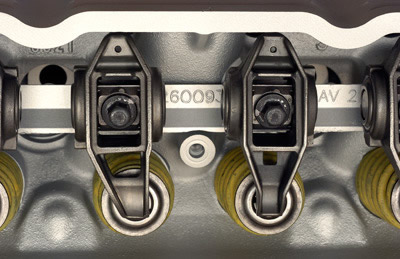

Another new feature of the LS3 valve gear is offset intake rocker arms. Similar in concept to those used for the current Z06's LS7, they have a 1.7:1 ratio. The offset is .246-in. and exists so the pushrod could be moved sideways about a quarter of an inch, allowing those wider intake ports.

Taking another page from the Z06 engine book, the LS3 intake valve, because its larger diameter increases mass, now has a hollow stem to get weight back down to where the valvetrain is stable to the same, 6600 rpm rev limiter used on the LS2. The LS3 valve spring used is the "double-shotpeened," Gen 3/4 high-performance unit, originally developed for the LS6 and used in LS2.

Intake and Exhaust

The Corvette intake manifold has, once again, been changed. One reason is the intake port floor in the head is much higher and the port is wider. That, alone, drove development of a new intake.

Gen 3s all used a glass-reinforced Nylon-6,6 intake which was manufactured using the lost core process. In 2005, for the Vette's first Gen 4, the LS2, GM switched to a different material, Nylon-6, and went to a vibration-welding manufacturing process. For the LS3, Powertrain decided to go back to a one-piece, lost-core, intake.

"Since the ports moved up and their shape changed," John Rydzewski stated, "we needed a new intake. It's still made of Nylon-6 but it's now done with the lost core process. The manifold is specific to passenger car applications that use this cylinder head.

"A vibration-welded intake has different shells. One port can be a combination of an upper portion and a bottom portion with the runners welded together on the side. It's a pretty good seam, but there might be a little crosstalk (port-to-port leakage) which can rob you of some power. We had seen that in some applications, so we went to a lost-core intake.

"We also reshaped it for better flow. Yoon Lee, who's been on the program for a few years, did the development. Compared to LS2, he reduced restriction by 2-3% at 13.5mm lift. It's just a smoother path, right down to the head. There's some extra structure-some different type of webbing on the bottom of the manifold-to stiffen it up. We, also, went to metallic compression limiters (inside the manifold bolt bosses) vs. the previous composite compression limiters. You've got the long columns and, with time, composites-if you do over-tighten-can creep."

"Creep" is a bit of a misnomer because it implies that the manifold, as a unit, moves. Better terms might be "extrude" or "deform". If you tighten the intake manifold bolts on a plastic intake, over time and especially if the bolts are over-tightened, the plastic may extrude, radially, away from where the fastener load is applied.

For long-term durability," Rydzewski added, "we don't want any creep in our manifold, so we're applying 'Bill-of-Design'-more of what we learned (that metallic compression limiters in the bolt bosses eliminate creep) from other applications."

LS3's injectors come from LS7. With 30-36 more horsepower, LS7's 5-gram/sec. injectors were necessary. The throttle body carries-over from the LS2. There are no functional changes to the positive crankcase ventilation (PCV) system. The induction system ahead of the throttle body is from the Z06 but with some quarter-wave tuners added to attenuate certain frequencies of intake noise.

The exhaust manifolds are similar to the units introduced in 2005 on LS2 but have a slight change in each exhaust runner where it bolts to the head to match the revised exhaust port exits.

These manifolds were revolutionary in '05, as GM employed a new material, cast iron with higher silicon and molybdenum content, which made a stronger casting. As a result, the wall thickness of the part could be reduced by about 25% and that took 10.5 lbs out of the car. A new MLS exhaust gasket was, also, released.

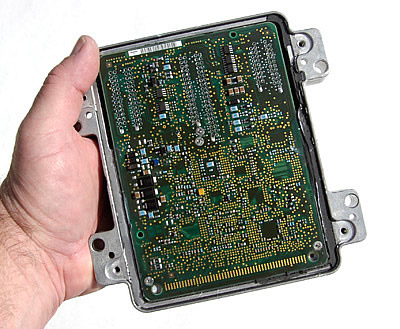

Engine Controls and Bin 4 Emissions

The engine control module (ECM) or "controller" as the guys who develop this stuff say, was new for 2006. Known internally as "E38, this new controller is part of GMPT's "Strategic Engine Management Complexity Reduction Initiative"-yeah, GM is like the Federal Government when it comes to thinking-up names. This program will result in only three engine management systems which share as many parts as possible.

The E38 has enhanced electronic throttle control (ETC) ability and it supports the 58x crankshaft position signals and 4x camshaft position signals which will be more common in coming years. It is a more thermally-robust design which can be mounted under the hood and close to the engine which reduces wiring harness length and complexity. It also uses connectors which meet standards set by the Electrical Wiring Component Applications Partnership (EWCAP) of the United States Council for Automotive Research (USCAR), a organization set-up by GM, Ford and Chrysler to foster the technology base of the domestic automotive industry.

As for the deep-geek aspects of the E38: its CPU is Motorola's PowerPC. It's a 32-bit, RISC processor running at 40Mhz with 64Kb or RAM and 2 Mb of flash ROM. The RAM nonvolatile and ignition independent and the flash EPROM, which contains the E38's calibration is nonvolatile and battery independent. E38 the carries over to the LS3 and is used on all Corvettes.

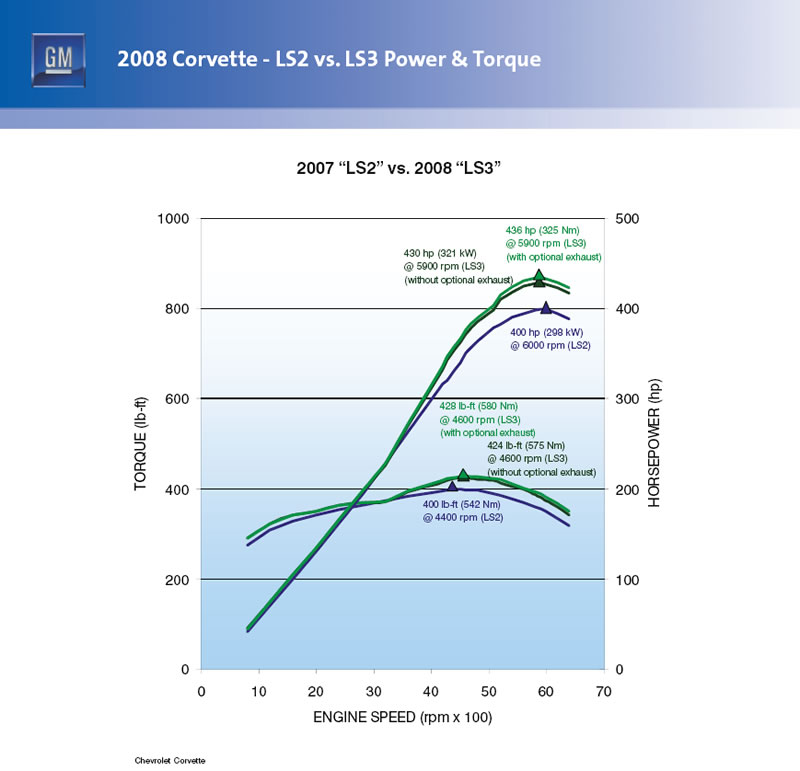

One capability enabled by the combination of the E38, LS3's improved combustion dynamics and enhanced emissions control devices, is compliance with the more stringent, Tier 2, Bin 4 exhaust emissions standard. These "bins" get tougher in a downward progression so, Bin 4 is cleaner than Bin 5. "With Bin4 emissions," John Rydzewski told us, "useful life hydrocarbon emissions are reduced by over 12% and useful life NOx emissions are reduced by over 40% compared to the LS2."

We should add that, Bin 4 emissions compliance comes with 36 more horsepower and no change in fuel economy. Plus if you order the LS3 with NPP exhaust, the darn car sounds better.

More performance, more green, less gas, better sound? Works for us!

Looks like the LS3 Team at GM Powertrain did a damn fine job.

The Corvette Action Center would like to thank Sam Winegarden, John Rydzewski, Lou Oniga, Jim Hicks, Tom Read and Susan Garavaglia of GM Powertrain Division for their assistance with this article.

For space reasons, this story could not cover many details of the LS3 which carried-over from past engines. For more information on the LS1/2/6 engines see the following web resources:

LS2: https://www.corvetteactioncenter.com/specs/c6/2005/sequel5.html

Ruthless Pursuit of Power: 2008 Edition - What of the Future?

|

| Corvette Chief Engineer, Tadge Juechter (left) and Powertrain's, Sam Winegarden, address automotive media at the Bowling Green Assembly plant. Image: Author |

No use without permission, All Rights Reserved

In researching our LS3 story, the CAC attended a late-April media briefing staged at the Bowling Green Assembly Plant in conjunction with the C5/C6 Registry's "Birthday Bash" event. GMPT's Executive Director for Engine Engineering, Sam Winegarden, gave part of the briefing. In Q&A afterwards, we asked Mr. Winegarden, the top "engine guy" at GM, about the mid-term future of Corvette powertrains with respect to the Bush Administration's intent to overhaul corporate average fuel economy (CAFE) standards.

Under President Bush's proposal, CAFE would go up 4% annually for seven years starting in 2010. By 2017, this would mean a little over 30% above the gas mileage of MY09 product. Right at our deadline, the Senate passed a bill which, if signed into law, would mandate a 40% increase in CAFE by 2020. Regardless if it's 30 or 40%, the prospect of this has not only GM, but any manufacturer building cars for sale in the U.S. scrambling to assess product plans the next decade.

We asked Mr. Winegargen what his strategy would be to insure that an engine in a 2013 C7 would be capable of 12% better fuel economy while providing the performance and drivability Corvette customers expect.

The first technology he cited was...

Full Story...

|

|