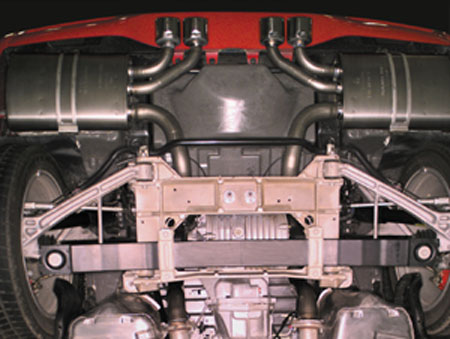

2001 - 2004 Corvette Z06 Titanium Exhaust System

A press release from ArvinMeritor that takes an in-depth look at the 2001 - 2004 Corvette Z06 titanium exhaust system.

The following information comes from a press release published by ArvinMeritor, the company that manufactures the Z06 Corvette's titanium exhaust system. This press release and photographs are copyright - ArvinMeritor Corporation

| Click on pictures for enlarged image. | ||||

|

|

|

||

What helps the CORVETTE Z06 really fly?

A major automotive ADVANCE:

The FIRST mass-produced exhaust system in TITANIUM - the AEROSPACE metal.

INNOVATIVE engineering and an EXCEPTIONAL metal generate an automotive TRIUMPH.

THE CORVETTE Z06 CHALLENGE: MAKE IT LIGHTER, MAKE IT FASTER

For GM, pushing the performance envelope on the 2001 Z06 was essential.

To that end, GM issued Arvin the challenge: design and manufacture a

new exhaust solution that is lighter weight than stainless steel systems,

meets underbody packaging constraints and contributes to making this

car the highest performance Corvette ever.

THE CORPORATE COLLABORATION: A TITANIUM SYSTEM

Arvin, the leading global designer and producer of original equipment

exhaust systems, first began investigating the use of titanium in 1993

for its light weight, strength and corrosion resistance. For years Arvin worked

with TIMET, the largest titanium manufacturer and distributor in the

world, on projects exploring titanium automotive applications. In response

to the GM criteria, Arvin recognized an optimal new exhaust system could be

made from titanium and the firms partnered to deliver the solution.

THE AEROSPACE METAL: PROVIDING UNIQUE BENEFITS

Titanium is a staple of aerospace due to its high strength-to-weight

ratio

and is essential in many industrial processes due to its natural corrosion

resistance. It is the fourth most abundant structural element, occurring

as rutile ore in common black beach sand, which is frequently mined

in Australia. TIMET refines the ore and processes the metal at its

manufacturing facilities in the United States.

THE REMARKABLE RESULT: RACING TECHNOLOGY IN A STREET CAR

The 26-pound titanium muffler and tailpipe assembly replaces a 44-pound

stainless steel system. The 41% weight savings means improved performance:

faster acceleration, better handling, higher cornering speeds, shorter

braking distances and increased fuel economy. In addition, titanium's

natural corrosion resistance and durability give the system a virtually

unlimited life span. The achievements in titanium manufacturing, exhaust

design and testing will contribute to future advances in exhaust systems

and a broader use of titanium on mass-produced vehicles.

|

INNOVATIVE DESIGN — FOR FUNCTION AND FABRICATION

The Arvin design addresses the differences between titanium and stainless

steel, including characteristics such as springback, vibration and resonance

frequency. New muffler components were custom developed for titanium

fabrication and a unique acoustic tone, to meet GM sound requirements.

A NEW GRADE OF TITANIUM — FOR MASS PRODUCTION

To meet both performance and production rate demands, TIMET and Arvin

collaborated to develop a new Exhaust Grade of commercially pure titanium.

Special surface conditioning allows efficient fabrication to help meet

the cost criteria set by GM for using titanium on a production car.

LIGHT WEIGHT AND STRENGTH — FOR Z06 PERFORMANCE

The titanium system is as strong as steel, but weighs just 26 pounds

– 41% less than a comparable stainless steel system. The reduced weight translates

to improved performance and increased fuel efficiency.

CORROSION IMMUNITY AND DURABILITY — FOR UNLIMITED LIFE

Titanium has a natural oxide layer that provides immunity to external

corrosion from road salts, as well as to internal corrosion from sulfur-rich

engine exhaust. The system will experience no pitting or rusting, even

at the welds. Corrosion immunity also means the exhaust is designed with no

corrosion allowance, permitting thinner gauges than steel, which contributes

to the weight savings. In a production vehicle, the system will far

outlast anything made of stainless, resulting in fewer warranty claims and increased

customer satisfaction.

Why a TITANIUM exhaust system for the CORVETTE Z06?

T-3TM — TITANIUM, TECHNOLOGY AND TESTING

When titanium emerged as the solution to the GM performance challenges,

the manufacturing technology to produce titanium mufflers in mass-market

quantities didn't exist. Working with TIMET to optimize an Exhaust Grade

of titanium, Arvin successfully adapted its stainless steel stamping, bending,

cold forming and welding methods to accommodate the structural differences

between stainless and titanium. New testing and computer models were

also developed to ensure GM durability requirements were met, determine optimum

material gauges and achieve desired acoustic tuning. Arvin has captured

this proprietary process development technology under the name T-3TM for

Titanium, Technology and Testing.

AESTHETIC APPEAL — FOR THE CORVETTE LOOK AND SOUND

To create the distinctive Z06 exhaust outlet scoop, Arvin developed

new technology to cut the metal on an angle and curl it on a tight radius.

Further showcasing the unique look, titanium's oxide film takes on shimmering

tones of blues, purples and golds as exhaust raises the temperature

of the pipes. These colors evidence and enhance titanium's natural corrosion

resistance. Finally, to generate the singular Corvette exhaust resonance,

Arvin designed a new internal muffler configuration and used advanced

acoustic

techniques to tune the muffler.

GREEN METAL — FOR ENVIRONMENTAL RESPONSIBILITY

Titanium is environmentally sound. It is completely inert, non-toxic, 100% recyclable and its production leaves no harmful by-products. Titanium does not degrade or release anything into the air, water or ground.

MIKE DANIEL

30903 NORTHWESTERN HWY.

SUITE 203

FARMINGTON HILLS, MI

48334

www.arvin.com

KURT FALLER

1999 BROADWAY

SUITE 4300

DENVER, CO

80202

www.timet.com